Tenna Asset Tracker

As the product designer, I worked closely with our product manager and a team of developers to build the solution in an agile process.

Time Frame: 2016-2018

My Role: Product Designer

The Challenge

Today, companies rarely track their small to mid-sized assets due to the expensive nature of GPS location trackers. This equipment and materials were often lost or unaccounted for resulting in unnecessary purchases and under-utilized assets.

This financial strain significantly impacted construction companies, prompting our leadership team, hailing from Conti Construction—a construction company with a century-long legacy—to recognize a crucial gap in the market. Determined to address this challenge, they embarked on a mission to develop a product tailored for internal use and external sales.

This endeavor laid the groundwork for Tenna. Through meticulous exploration, we aimed to revolutionize asset management in the construction industry, providing an effective solution for tracking and optimizing the utilization of valuable resources.

Discovery

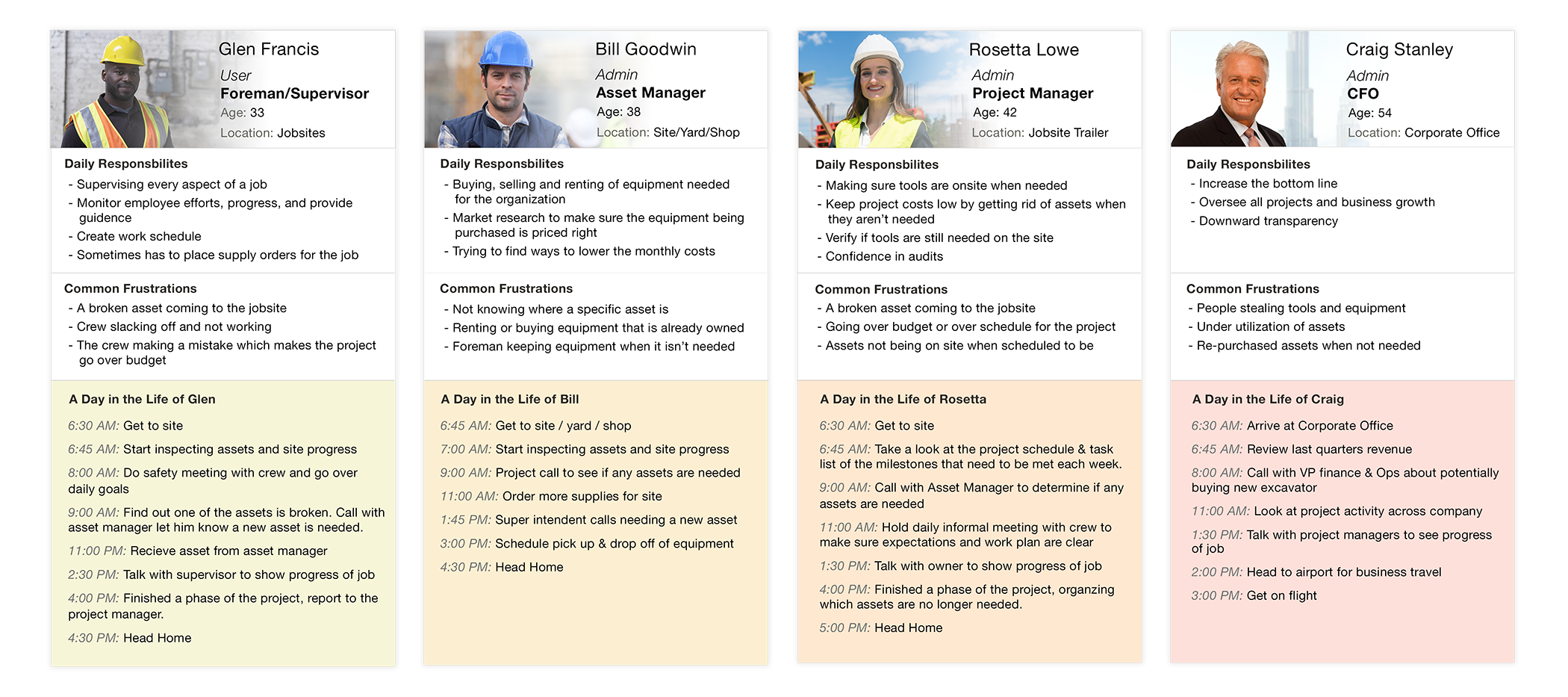

We interviewed foremans, supervisors, asset managers, projects managers and stake holders to gain an understand of their frustrations and responsibilities...

1. What is your day to day process?

2. Who do you interact with on a daily basis?

3. How do you track your smaller to mid-sized assets?

4. What is your process like if you receive a broken asset on the job site?

5. How do you handle lose of assets to theft or misplacement?

Etc.

We discovered some common themes.

Lack of Oversight & Financial Burden

Following thorough user research and an examination of current solutions, we determined that the market lacked an affordable technology to streamline the tracking of small to medium-sized assets. Existing technologies were impractical due to their high costs and were only suitable for large, heavy machinery.

This gap in the market impacted all levels of construction companies, from foremen dealing with damaged assets to project managers unaware of underutilized resources, and leadership making redundant asset purchases.

User Personas

Based on insights gathered from user research, we developed user personas to inform our product, branding, and marketing strategies. By employing these personas, we adopted a user-centric design approach, enabling us to empathize with our users and effectively address challenges that resonate with their needs.

Product Decisions

Based on our findings, it became evident that every team member relied on cell phones and tablets for their work. Recognizing the need for a mobile-first product and unable to employ GPS tracking, we opted for a simpler, cost-effective solution: QR codes and Bluetooth Tracking.

QR codes gained popularity across various industries due to their user-friendly nature and simplicity. We successfully devised a method to easily assign assets to QR codes, allowing a straightforward scan to provide all the essential information.

Utilizing robust QR codes emerged as a cost-effective means to track smaller assets efficiently. A simple scan updates these assets, enabling the entire chain of command to access details such as location, project association, frequency of use, and maintenance status.

Bluetooth tracking made the assets even easier to update but at a slight increase in price. Any device with their bluetooth connected could easily walk by equipment without even scanning and it would automatically update location and project usage.

Building MVP

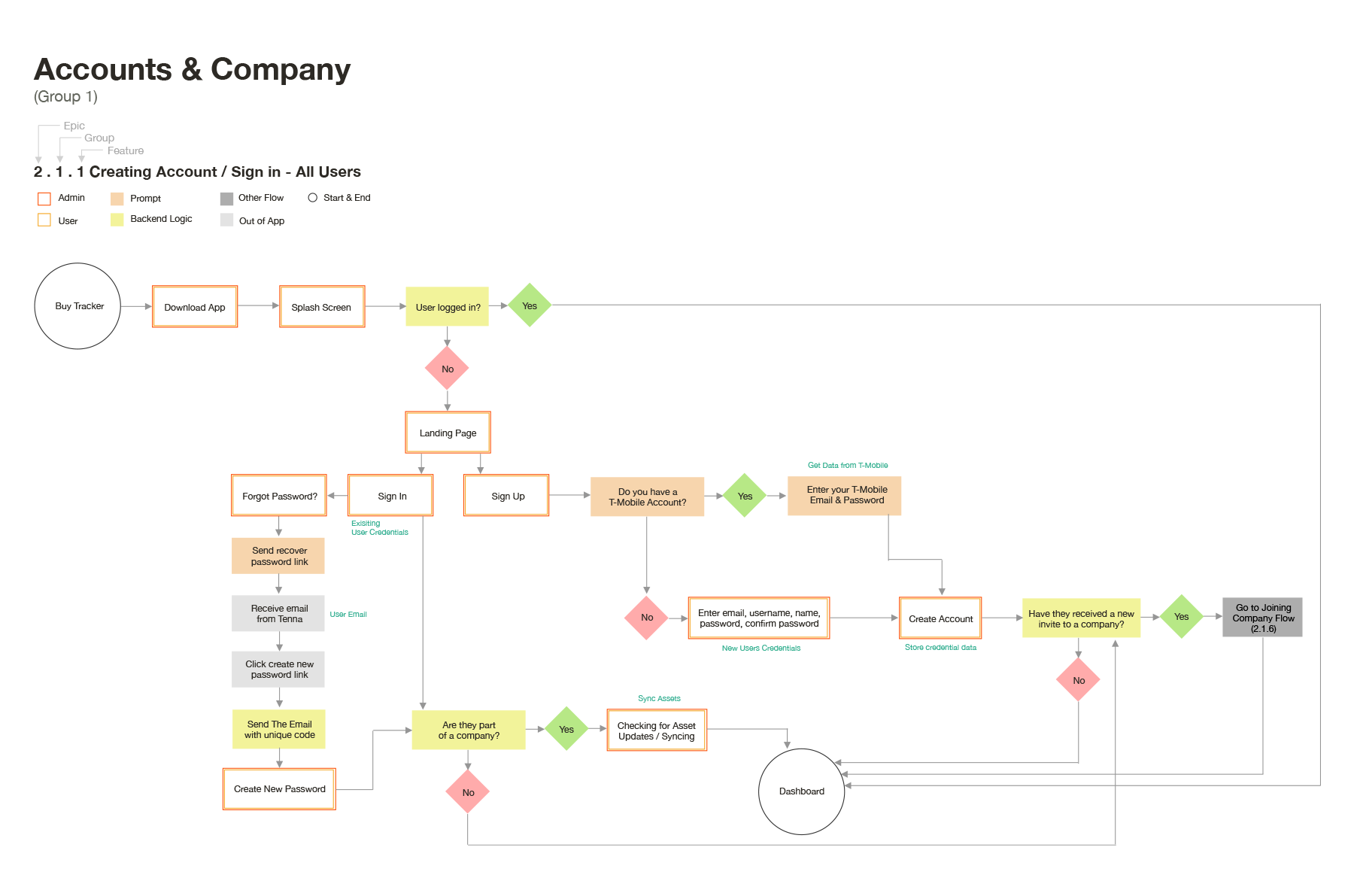

User Flows

Initially, we mapped out user flows, recognizing the importance of minimizing disruption for construction workers. It was crucial to automate the asset update process through a simple scan, ensuring efficiency without hindering their workflow. Additionally, to address varying access needs, we implemented distinct user types such as admins, users, and company leaders, allowing selective information visibility.

s

s

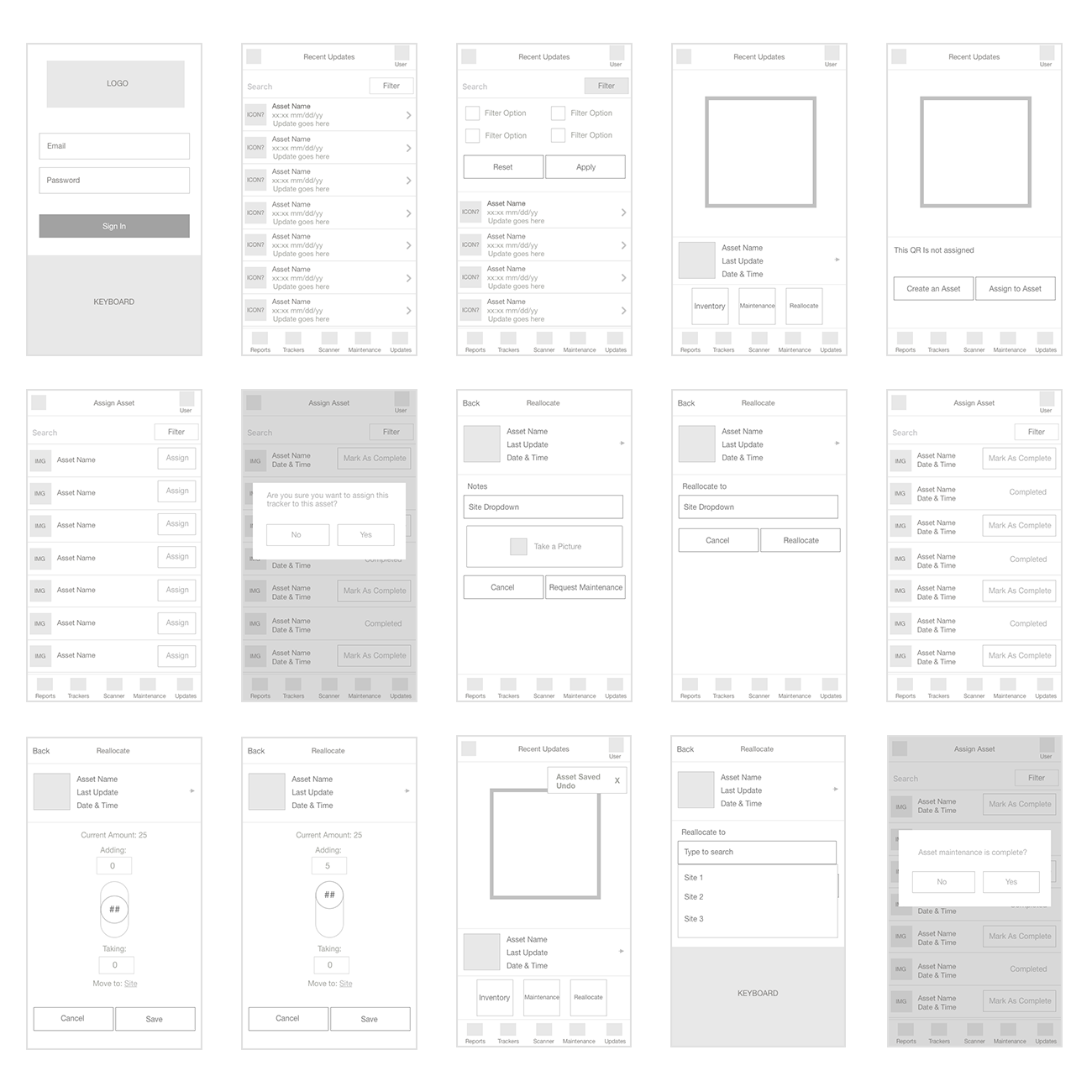

Wireframes

Next, I worked on the wireframes to establish the overall flow for the experience. While the product team can visualize creative concepts, stakeholders need tangible representation to understand the user interaction. Presenting wireframes to executives allows them to provide valuable feedback and ensure we are meeting their needs.

.

Sprint Process

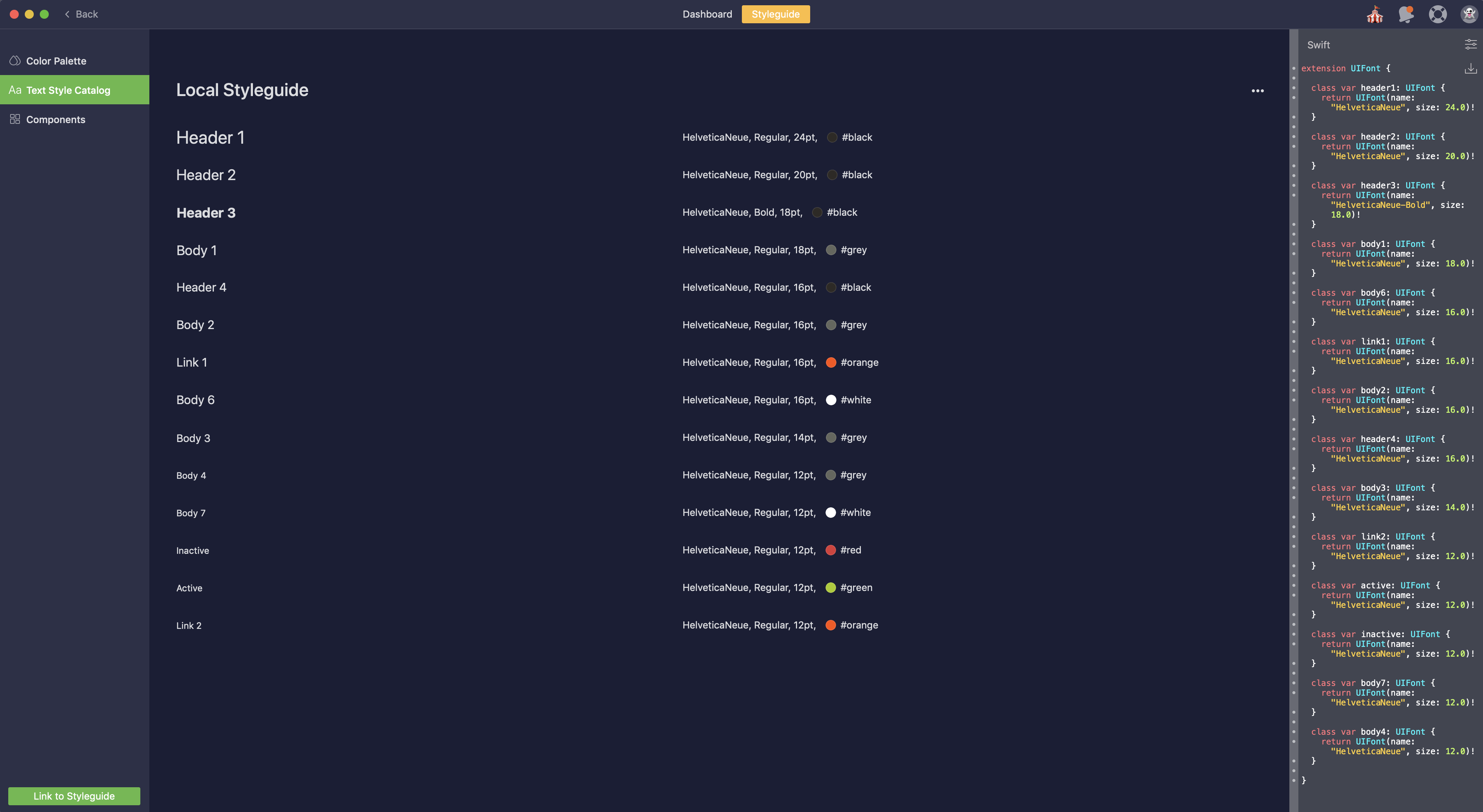

Design System

The development of this product followed a 2 week sprint agile process. Initially, we obtained approval from stakeholders, and subsequently, we delivered the product prototype to the engineering team. Our approach involved utilizing Sketch and InVision for styling and ensuring a cohesive overall user experience.

.

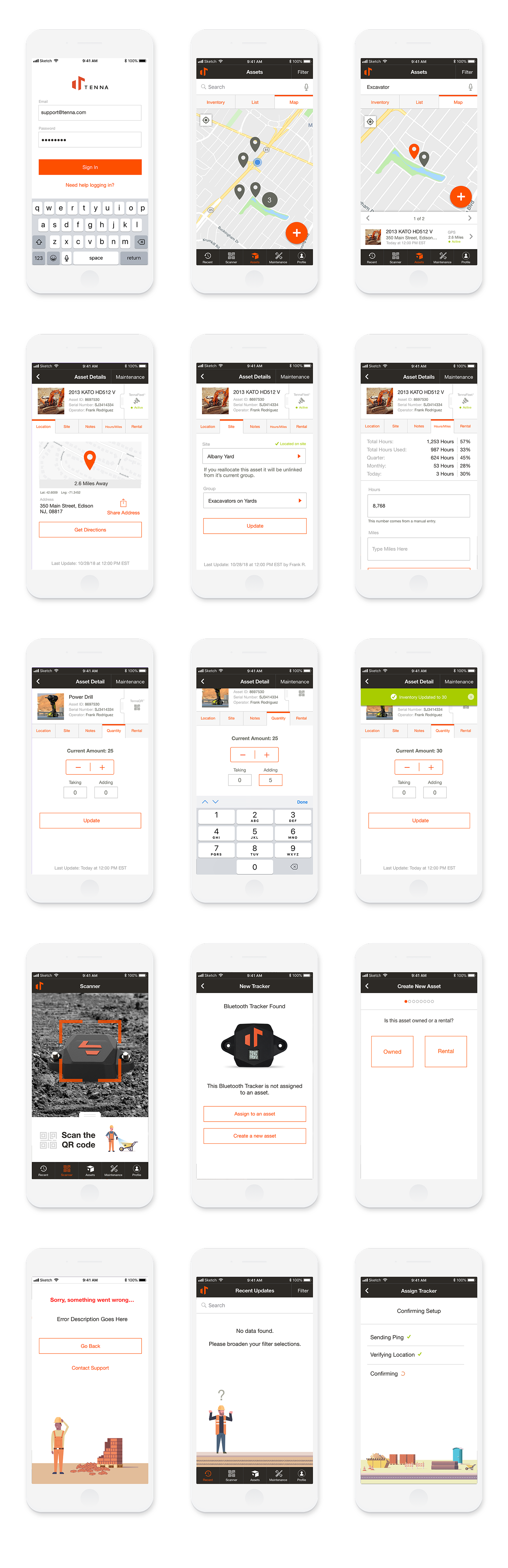

Final Product

High Fidelity

The ultimate outcome was a cross-platform app available on iOS and Android. The UI design aimed to facilitate swift navigation through data in a seamless and visually appealing manner. We incorporated custom animations and graphics to infuse a sense of branding and gamification into the app.

.

Interaction Design

I produced interaction design videos to provide clear guidance to the developers regarding the expected interactions on each screen. This helped avoid delays and minimized questions developers might have had about the user experience.